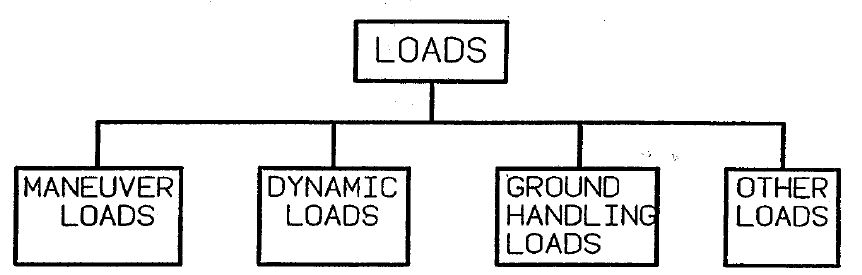

External loads are generally defined as forces and loads applied to the aircraft structural components to establish the strenth level of the complete aircraft. The structural loading may be caused by

- air pressure

- inertia forces

- ground reactions during landing and taxiing

- ground handling (hoisting, packaging, shipping ...)

Structural design criteria

In order to apply structural design criteria the following parameters should be known

- Gross weight requirment

- Performance capabilities

- Stiffness

- Aerodynamic characteristics

- Landing gear features and characteristics

- Operating altitudes

- Load analysis requirements

Structural design criterias could be grouped into two groups

- Under control of the pilot. Airplane must be capable of performing mission in a profitable as well as safe manner and it is assumed to be operated by qualified personnel under well-regulated conditions.

- Beyong control of the pilot

- turbulent air

- sinking speed during landing

- taxiing over rough terrain

- engine failure

- etc

Structural stiffness

In high speed aircraft, structural stiffness requirements are important to provide adequate strength to prevent the following phenomena:

- Flutter

- Control surface reversal - control surface is loosing its effectiveness due to weak torsional stiffness of wing box

- Static divergence - wing stricture becomes torsionally unstable as the angle of attach increases

Aerodinamic characteristics

Some of the necessary information must be determined by analysis and wind tunnel tests:

- Basic aircraft stability characteristics

- Pressure distribution over the wing, empennage and fuselage

- Control surface hinge moments

- Pressure distribution over high lift devices, such as flaps and slates

Load analysis

Design loads are determined for various structural components using computers. The following analysis are required:

- Maneuver loads analysis

- Gust loads analysis (static and dynamic approaches)

- Landing load analysis (rigid airframe and dynamic analysis)

- Ground handling loads (rigid and elastic aircraft)

- Control surface reversal characteristics and load distributions

- Dynamic analysis for control surface oscillatory conditions due to "black box" (autopilot ot yaw dumper) failure

- Flutter analysis and tests (wing tunnel and flight tests)

- Buffet and vibration

Weight and Balance

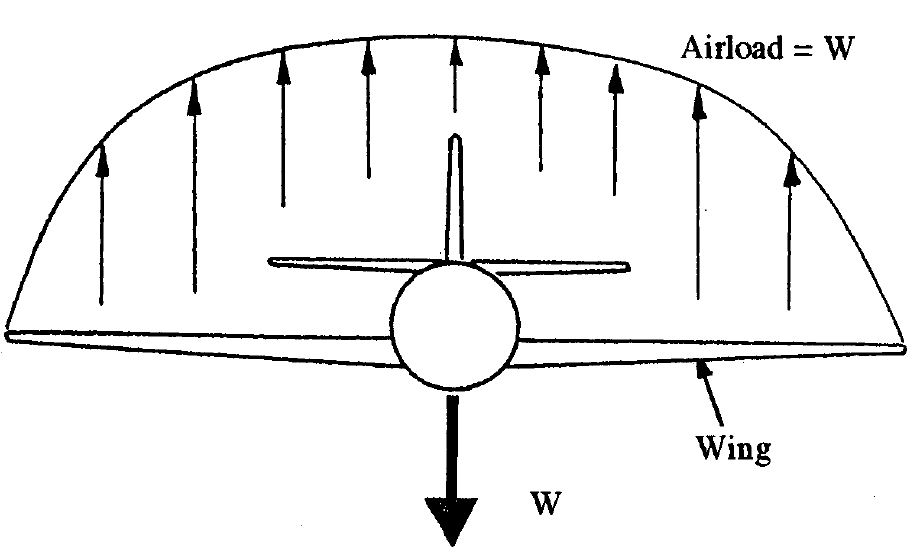

Structural design loads affect the weight of the airframe structure, and the weight of the aircraft influences the magnitude of design loads.

Weight requirements

Structural weight requirements are established as a part of the basic gesign of the aircraft to accomlish mission desired. These weight vary from the minimum gross weight to the maximum gross weight for which the aircraft is designed. Other requirements are:

- center of gravity limits. During the flight the c.g. travel is limited by the stability and control capabiliites of the airplane. Forward cg is limited by the ability of the tail to maintain balance during flaps-down landing approaches. Aft c.g is limited by so-called "maneuver point" at which the aircraft reaches neutral stability.

- weight distribution of fixed items (engines, fuel tanks...) to allow maximum use of aircraft cargo and passenger compartments

- Fuel requirements.

Major aircraft weight

Aircraft gross weight and detailed distribution of weight have a large influence on structural design loads. For examlpe, wing-up bending is almost a direct function of aircraft gross weight

Another example is the effect of the aircraft gross weight on design load during the landing when airplane contact the ground at a given sinking speed.

Typical aircraft major design weights are: a) Take-off gross weight - maxumum gross weight to perform specified mission. The aircraft is generally considered as containing capacity of fuel and maximum payload. Take-off gross weight is considered for taxiing conditions and flight conditions, but the aircraft need not to be designed for landing at this weight.

b) Design landing weight - maximum weight for the landing operation. It is reasonable to expect that a predetermined amount of fuel is used up before the aircraft is expected to land. Using Take-off gross weight for landing cases would add extra weight and penalyze aircraft. In many instances fuel dump provisions are installed on aircraft to reduce weight in emergency landing. Design landing weight is critical for fuselage and wing down bending during landing.

c) Zero-fuel weight - maximum weight with zero fuel aboard. It defines the summation of weight of empty aircraft, items necessary for operation (crew, engine oil, etc.) and cargo with passengers. This condition is usually critical for wing-up bending.

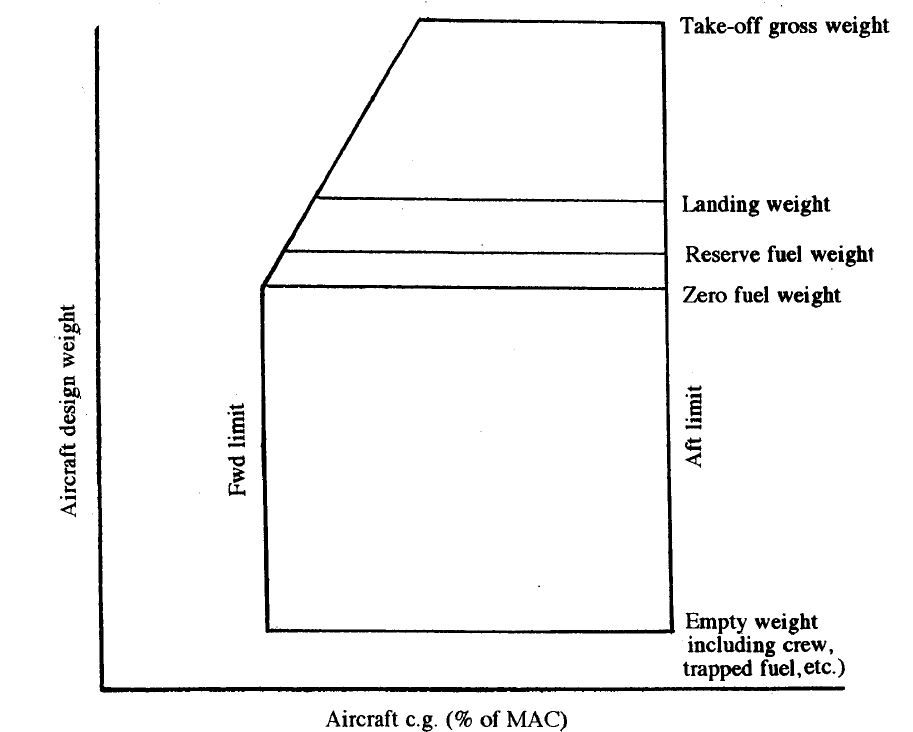

Center of gravity envelope

The combination of design weight and aircraft center of gravity location are very important. A plot is made of the variation of c.g. with the design weight. An envelope enclosing all extremes of the variation is determined for design.

Weight distribution

Once the critical loading is determined, a distribution of the dead weight is necessary. An accurate distribution of weight is important because the dead weight of fuselage, wings, cargo, ect, contributes to a large part of the loading.

The effect of weight distribution can be realized by considering the distribution of mass items of cargo within a fuselage. Whether these large masses are condensed about the centerbody or placed at extreme forward or aft locations wil influence greatly the magnitude of down-bending experienced by the fuselage forebody or aftbody during a hard landing.

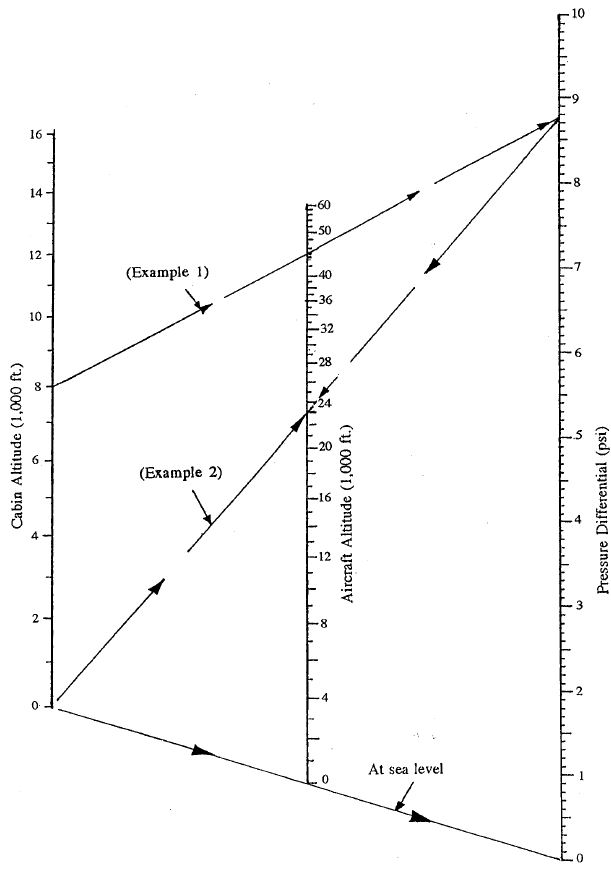

Fuselage pressurization loads

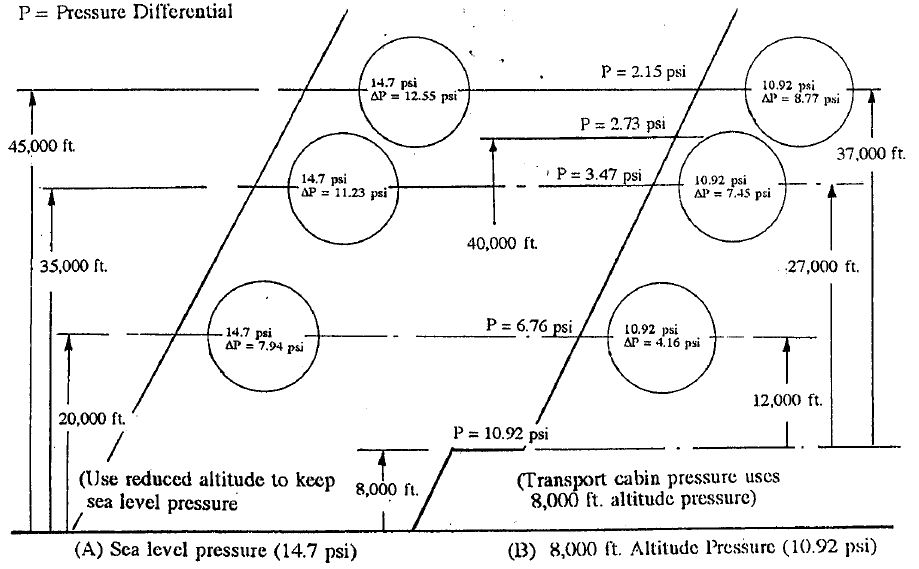

Fuselage pressurization is an important structural loading which includes hoop and longitudinal stresses in the fuselage. Pressurization must be combined with flight and ground loading conditions. The most important consideration for establishing the fuselage design pressure is the effect of altitude on cabin pressure and the fuselage must be designed to maintain cabin pressure.

When aircraft fly above 15 000 ft. (~4 500 м) it is required that the cabin pressure to insure comfortable conditions for passengers during flight.

Determination of pressure differential:

- Pressure differential can be obtained from a nomogram

- in general, most commercial transport cabins are designed for 7 000 ft. altitude pressure

- at 8 000 ft altitude the atmospheric pressure is 10.92 psi

- the constant cabin pressure is 10.92 psi form the altitude of 8 000 ft to the designed altitude.

- Some executive aircraft may require at sea-level (14.7 psi) pressure differential

- if the aircraft is designed for a max flight altitude of 45 000 ft, the pressure differential is 12.55 psi

- pressure differential is 8.77 psi for 8 000 ft altitude pressure

- Most military transport cabins are designed for 1 000 ft altitude pressure

- Pressure differential is used to design the minimum thickness requirement for fuselage shell structure

Wing fuel pressure loads

Fuel pressure loads in the fuel tank can induce pressure which is normal to the tank wall structure (spars, ribs, covers). The most critical location is near the most outboard tank. The factors that affect the fuel pressure loads are:

- Tank geometry

- Load factors (Nx, Ny, Nz) on the aircraft

- Fuel density \(\rho=0.0307 lbs/in^3\)

- Aircraft maneuvers (pitch, verticlal gust, etc)