This loads are based on conventional scheme with nose landing gear. For configuration with tai gear refer to FAR 23 and FAR 25

The load factors (n) required for design for landing conditions are related to the shock absorbing characteristics of the main and nose gears. These characteristics are usually based on the results drop tests. From these results, the required design limit loads factors are determined. For commersial transports:

- for landing weight, the required descent velocity at initial impact is 10 fps

- at the design takeoff weight it is 6 fps

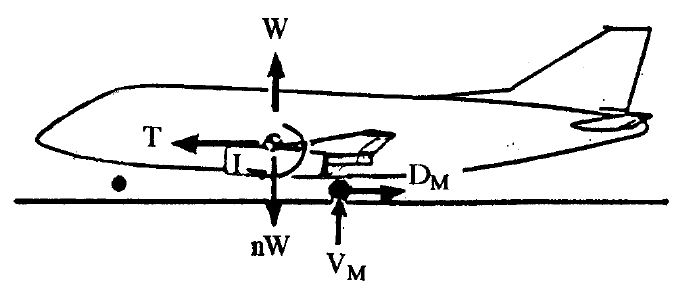

Level landing (LL)

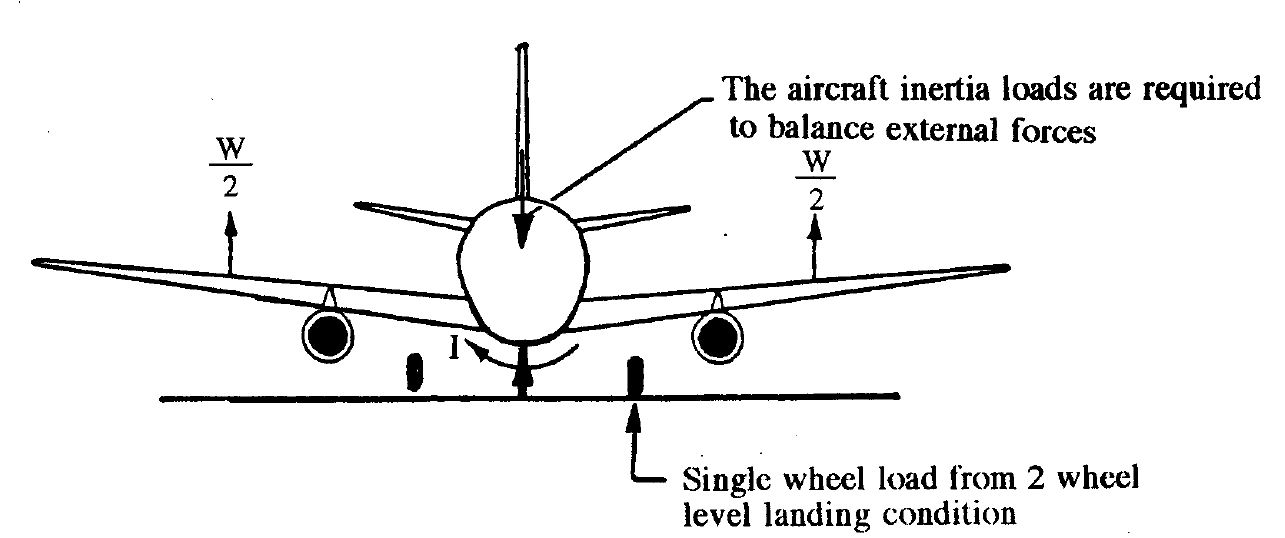

During level landing conditions the wings are supporting the aircraft weight (W) during landing impact. In the two point landing (LL2) vertical loads (V) and vorizontal loads (D), are applied at the wheel axles. These loads are reacted by aircraft inertia loads (nW and T). The moments created by this combination of loads is placed in equilibrium by the pitching inertia of the aircraft.

In three point landing case (LL3), the main and nose gears contact the ground simultaniously

The aircraft must be good for the landing loads which are equivalent to those determined for the combinations of gross weight and sink speed. The aircraft speed ranges from standard day stall speed to 1.25 hot day stall.

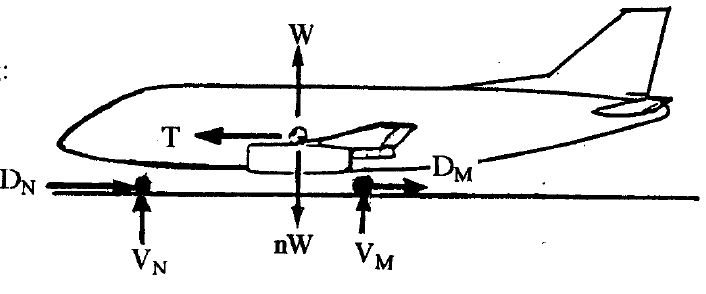

During the first part of landing impact, the wheel is spun up to aircraft rolling velocity by friction between the tire and the runway. This friction induces a short time, aft acting load at the axle which causes the gear to deflect aft. Aircraft is designed for the loads acting on the gear at instant of peak drag. These loads are determined by rational analysis, taking into account the time history of the events that occur during landing impact. Gear inertia loads are also included.

Following spin up, the gear springs back in a foward direction. A peak loading occurs at the point of maximum forward deflection. The aircraft must be designed for the vertical and horizontal loads occuring at this instant.

The three level landing situation that must be investigated is the one which occurs at the instant of maximum vertical ground reaction. An aft-acting horizontal load of \(0.25V_{max}\) is applied at the axle in this situation.

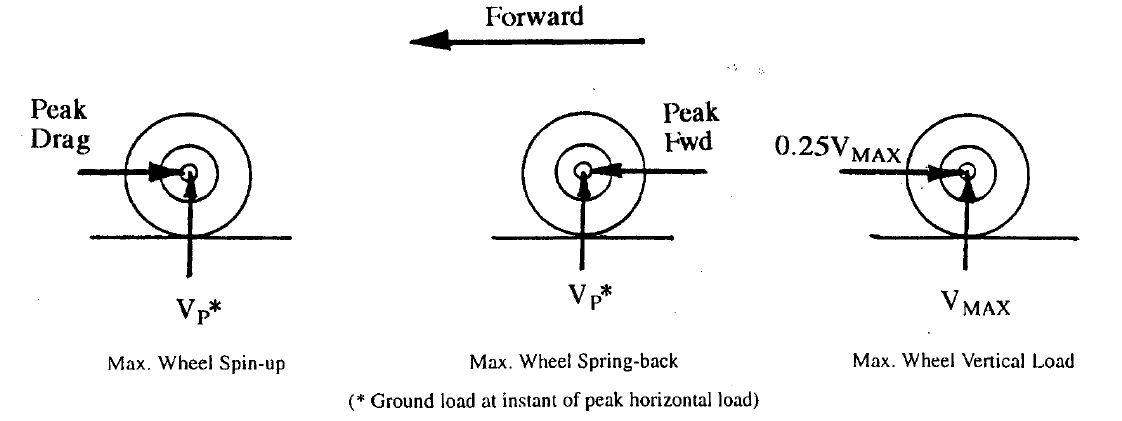

Tail-down landing

The tail-down landing is made at an extreme angle of attack. The angle is to be limited either by the stall angle or the maximum angle of clearance with the ground at the main wheel impact, whichever occurs first. Loading requirements are identical to those of level landing except that the condition of maximum wheel vertical load is not required.

One-wheel landing

The ground reactions are equal to those on one side for level landing. The unbalanced loads are reacted by aircraft rolling inertia

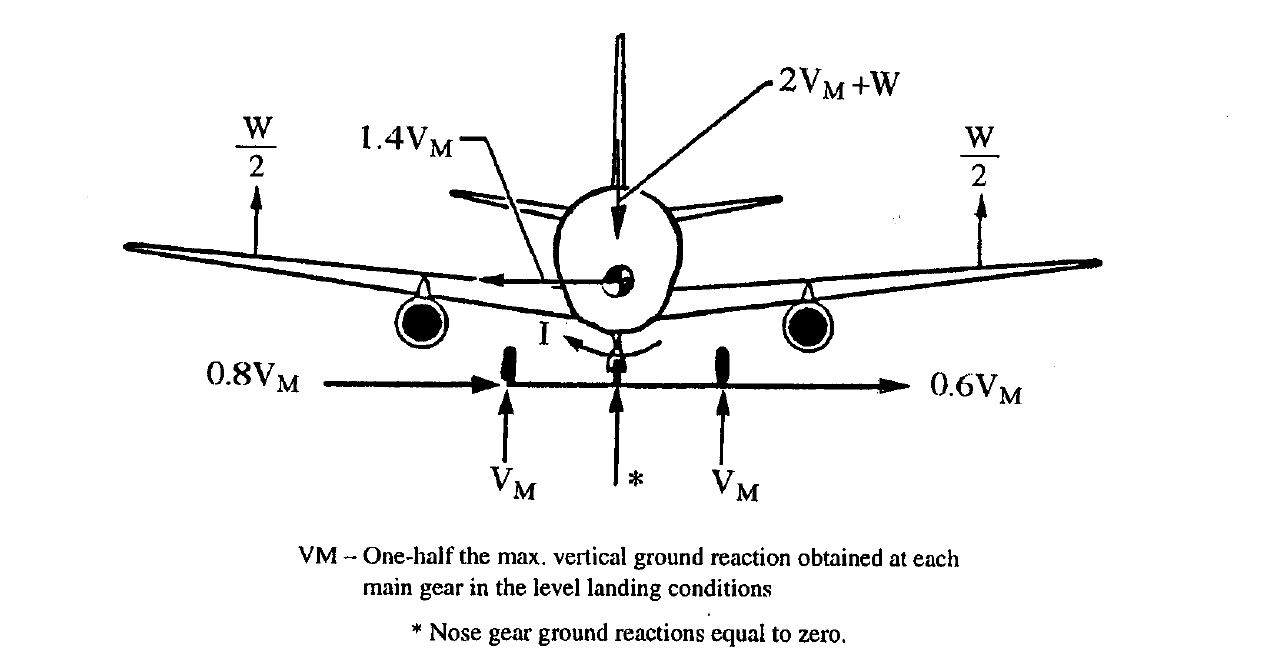

Lateral Drift Landing (LD):

The aircraft is in the level landing attitude with only the main wheels on the ground. The main gear loads are equal to one half the level landing maximum vertical main gear loads. Side loads of 0.8 of the vertical ground load on one side acting inward and 0.6 of the vertical ground load on the other side outward are applied at the ground contact point. These loads are resisted by aircraft transitional and rotation inertia.

Rebound landing:

Since the aircraft may rebound into the air after a hard landing, the gear and its supporting structure must be checked out for this condition. With the landing gear fully extended and not in contact with the ground, a load factor of 20 must be applied to the unsprung weight of the gear. The load factor must act in the direction of Oleo movement.

Dynamic loads

In actual circumstances aircraft structures will deform and vibrate under certain rates of loading. It must be shown by analysis that the aircraft can withstand the rate of loading applied to the structure by the landing gear during design load conditions