Taxiing

Taxiing conditions are investigated at the take-off weight and no wing lift is considered. Shock absorbers and tires are placed in their static position.

Take-off run

This loading occurs when the aircraft is taxied over the roughest ground and it is deigned practice to select a limit factor depending on the type of the main gear:

- 2.0 for single axle gear

- 1.67 for truck type gear

Brake and roll (BR)

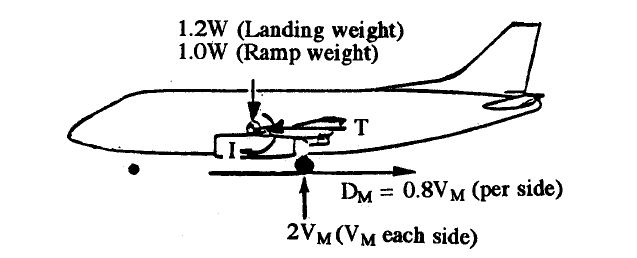

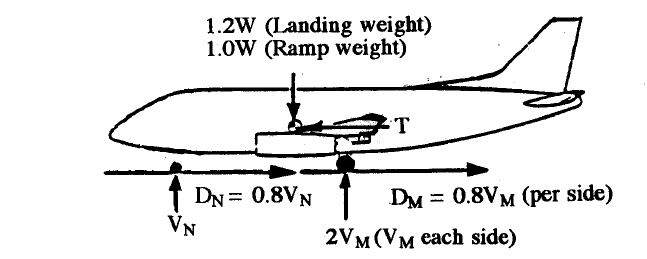

The aircraft is taxiing in a level attitude at either 1.2 times the aircraft design weight, or at 1.0, the design ramp weight (for abort take-off condition), without using thrust reversal pover. The brakes are applied and a friction drag reaction (coefficient of friction is 0.8) is applied at the ground contact point of each wheel with brakes. The drag reduction is equal to 0.8 times the vertical reaction load unless it cannot be shown that lesser loads cannot be exceeded because of brake capacity. Two attitudes must be considered:

1) Only the main gear are in contact with the ground with the pitching moment resisted by angular acceleration of the aircraft (2 point braking or BR2)

2) All wheels are on the ground and equilibrium is obtained by ground reaction (3 point braking or BR3)

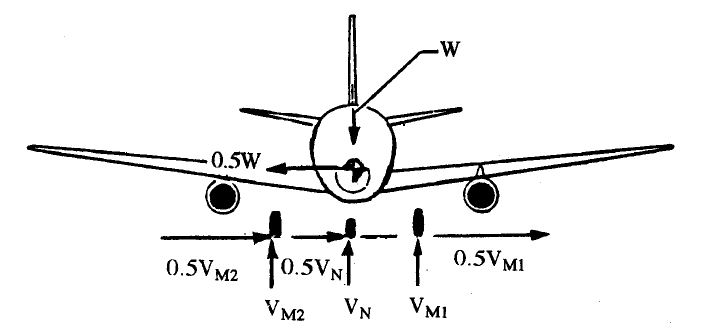

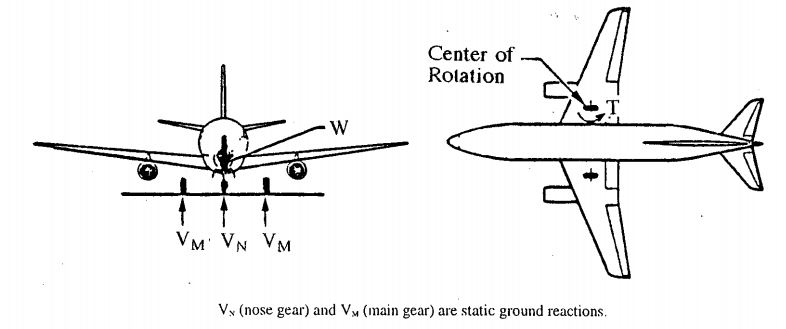

Ground Turning

Assume the aircraft is in a steady turn. The combination of turn radius and velocity is such that a total side inertia factor of 0.5 is generated by side loads on the wheels. The vertical load factor is 1.0. The ground reaction on each wheel is 0.5 of the vertical reaction.

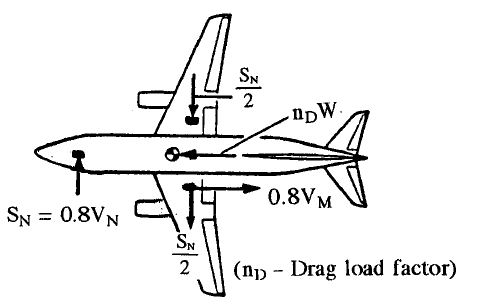

Nose Gear Yawing

There are two independent nose wheel yawning conditions

1) Nose Gear side load:

- The aircraft is standing on the runway at a vertical load factor of 1.0

- A side load of 0.8 of the nose gear vertical load is applied at the nose wheel ground contact point

2) Unsymmetrical braking (a moving situation in which brakes are applied to one main gear):

- A drag load is applied to this gear at the ground with a value equal to the maximum brake capacity but limited to 0.8 of vertical load gear

- Equilibrium is obtained by balancing side and vertical loads on the nose and main gear

- Any moment which would cause a side load on the nose gear greated than \(0.8V_N\) is balanced by aircraft inertia

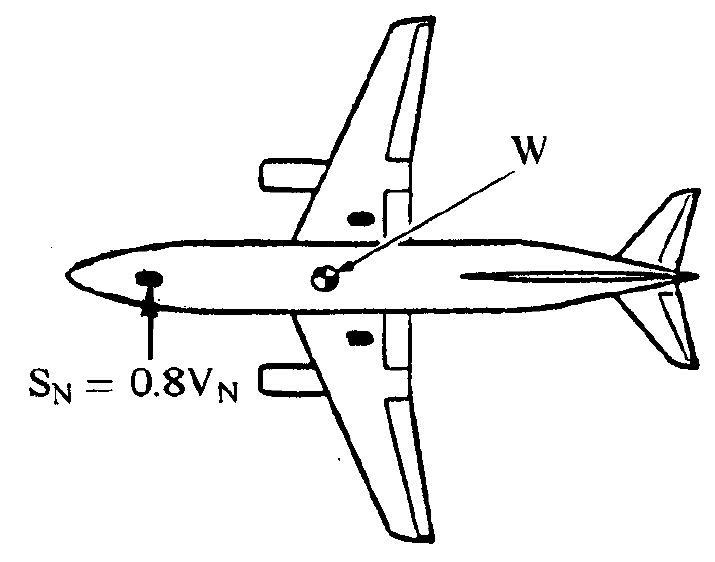

Pivoting

The aircraft pivots about one main gear which has its brakes locked. The limit vertical load factor is 1.0 and the coefficient of friction is 0.8. The aircraft is placed in static equilibrium by loads at the ground contact points. The aircraft is in three point attitude and pivoting is assumed to take place about one main landing gear unit.

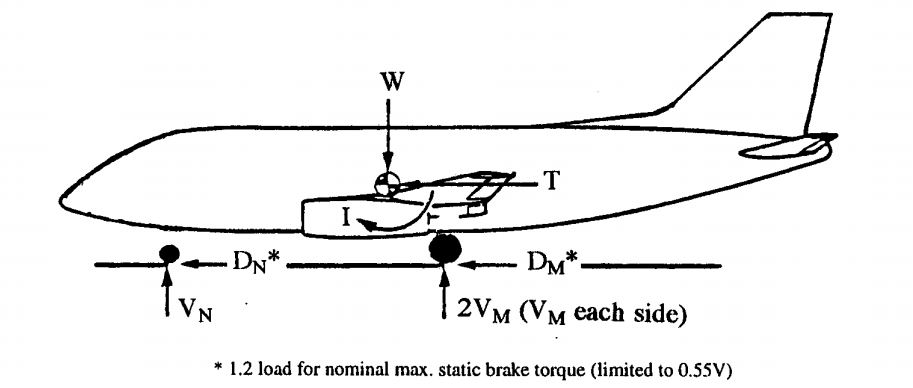

Reversed braking

In this condition, the aircraft is in the three point attitude at a limit load factor ща 1.0 and moving aft when the brakes are applied.

- Horizontal loads are applied at the ground contact point of all main wheels with brakes.

- These loads must equal 1.2 times the load generated at nominal maximum static brake torque except that they need not exceed 0.55t times the vertical load at each wheel

- The pitching moment is to be balanced by rotational inertia

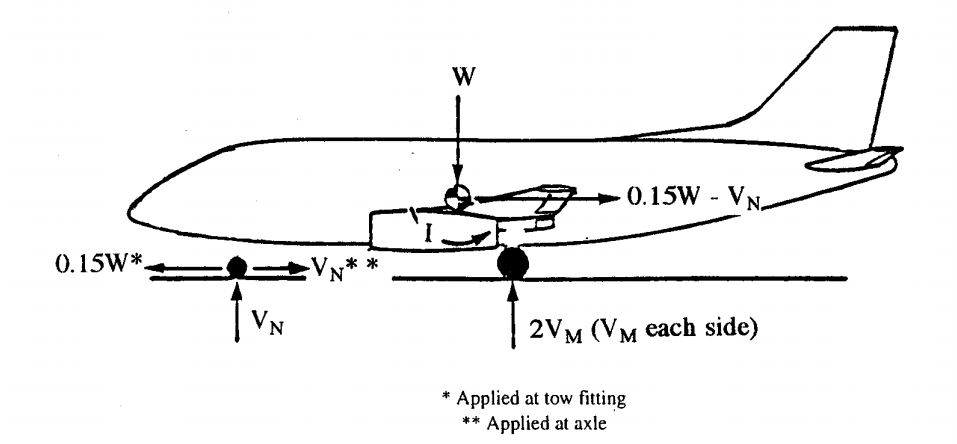

Towing

Towing requirements consists of many (approximately twelve) separate conditions which provide for main or nose gear towing fittings and fittings at other locations. The tow loads are obtained by multiplying the take-off weight by varying factors.

For example, a forward-acting load of 0.15W (take-off gross weight) occurs at nose gear towing fitting. The requirements call for a reaction equal to the vertical gear load to be applied at the axle of the wheel to which the tow load is applied. In this condition, it would be \(V_N\) at the nose gear and the unbalanced load is reacted by aircraft inertia

Unsymmetrical loads on multiple wheel units

The requirements for unsymmetrical loads on multiple wheel units (bogie, truck, etc) also involve all the ground load conditions that have been covered previously. For conditions in which all the tires are inflated?=, provision must bu made for such variables as:

- Wheels arrangement

- Tire diameter

- Tire inflation

- Runway crown

- Aircraft attitude

- Structural deflections

The case of one deflated tire on multiple wheel units or two deflated tires on gear with four or more wheels mus be investigated. There is usually a reduction in gear load requirements for deflated tyre conditions but this is not always true. For instance, in the drift loading condition, 100% of vertical load for the undeflated tyre condition must be applied.